In modern industry, the ability to adapt and innovate is crucial for maintaining a competitive edge. In an era where digital transformation is reshaping industries, the concept of Connected Worker solutions stands at the forefront of innovation.

These platforms are revolutionising how organizations manage their operations, enhance work productivity, and ensure safety across different industries. Among these advancements, Connected Worker platforms are driving the digital transformation of Standard Operating Procedures (SOPs) and work instructions, transforming how they are created, managed, and executed.

Impact of Connected Worker Solutions

Connected Worker platforms are comprehensive digital systems that integrate various digital tools to enhance productivity, safety, and collaboration among workers. These platforms create a real-time connection between workers and all the information and resources they need on the shopfloor.

Transforming SOPs and Work Instructions

Workers use SOPs as detailed guides with step-by-step work instructions to assist them in executing specific tasks. SOPs are essential for maintaining consistency, quality, safety, and compliance in daily operations. Traditionally, SOPs have been documented on paper, facing several challenges, including difficulty in updating, distributing, and accessing information. In addition, they can also be prone to error and hard to understand.

The digitalisation of SOPs and work instructions is at the core of the transformation enabled by Connected Worker Platforms. The integration of digitalised SOPs with digital work instructions creates a powerful alliance that is revolutionising industrial operations, making complex processes more accessible and easier to perform.

Digitalised SOPs

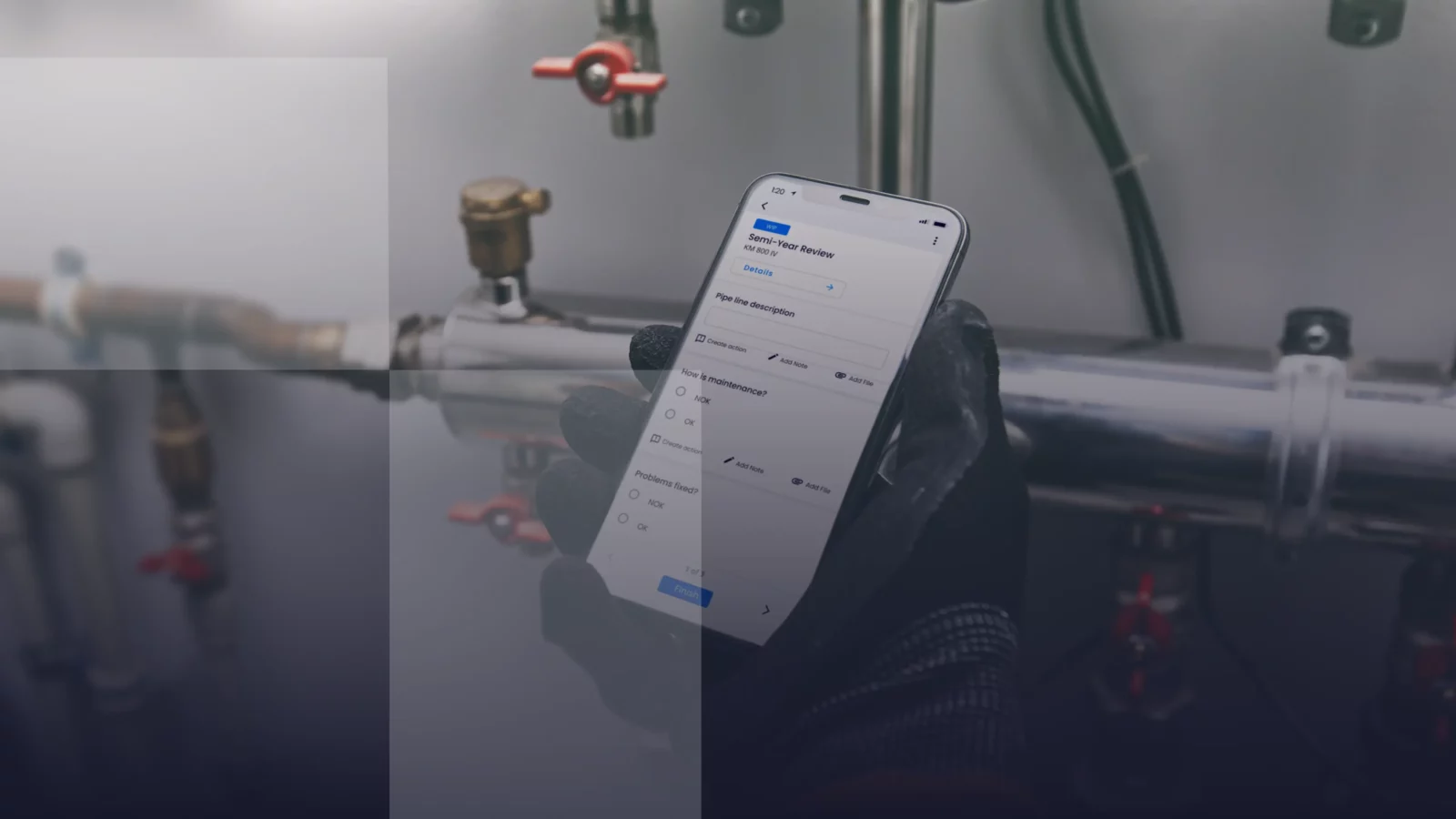

Workers can access digital SOPs instantly on their mobile devices (smartphones, tablets), wearables (Augmented Reality Glasses, Smartglasses), or computer terminals. This ensures that workers always have the most up-to-date procedures at their disposal. It eliminates the need for manuals and paper documents and reduces the time spent searching for information.

Management teams can update SOPs and promptly share them with the entire workforce. This ensures that everyone is working with the latest information, enhancing compliance and operational accuracy.

Digital SOPs allow for better tracking and enforcement of compliance. Supervisors can monitor adherence to procedures in real-time and generate reports to identify areas of improvement. This proactive approach ensures higher standards of quality and safety.

Digital Work Instructions

By incorporating visual instructions and multimedia elements such as images, videos, Augmented Reality (AR) overlays, and 3D models, digital work instructions provide clear step-by-step guidance. This visual guidance helps reduce errors, improves task accuracy, and enhances training.

Digital instructions can include validation steps (eg: QR codes and NFC validation), conditional steps, and automated checks. This consequently ensures that every worker follows every step correctly and consistently.

It is possible to customise digital work instructions for individual workers based on their roles, skill levels, and specific tasks. This personalised approach ensures that each worker has the most relevant and useful information boosting his efficiency.

New workers can leverage digital work instructions and interactive training modules to quickly get up to speed. This streamlined onboarding process reduces the learning curve and accelerates integration into the workforce.

Your Guide to Mastering SOPs and Digital Work Instructions

To navigate the complexities of digitalizing your SOPs and integrating digital work instructions through Connected Worker Platforms, our comprehensive Ebook “The Leading Ebook for SOPs and Digital Work Instructions”, is an invaluable resource.

Don’t miss out on this opportunity to transform your operations. Download Glartek ebook, “The leading ebook for SOPs and Digital Work Instructions”, and join us on this journey towards a more connected and efficient future.

Embrace the Future of Work Today

In conclusion, Connected Worker solutions empower organizations to equip their workforce with the necessary tools and information to excel in a rapidly changing environment. By transforming how SOPs and work instructions are managed and executed, these platforms are driving unprecedented levels of performance and safety in industrial environments.

The future of work is here, and it is digital, connected, and smarter than ever before. Do you want to learn more about connected worker technology? Explore our blog!