Safety first, always!

In today’s fast-paced industry world, where machinery and production lines pulse with activity, one unique priority stands above all others: the safety of the workplace. The heart of every organisation operations are the people who power it. Ensuring their well-being is a commitment and responsibility that goes beyond obligatory and legal regulations. Ensuring the safety of workers is of the most extreme importance.

Various safety protocols are implemented in the organisations daily routines, but there is one safety measure that is always present in most organisations. Personal Protective Equipment (PPE) plays a crucial role in safeguarding employees from potential workplace hazards. PPE includes many safety items that workers can use while carrying out their work, from safety helmets, safety glasses, gloves, and protective clothing, to respiratory protection equipment.

“600,000 lives would be saved every year if available safety practices and appropriate information were used.”

International Labour Organization

All this material needs to be in good condition, be used correctly, and ensure complete protection of the worker in the specific areas for which it was designed. To ensure all these parameters, it is necessary to assess the PPEs through regular Inspections so companies can guarantee and elevate their safety standards.

PPE INSPECTIONS IN THE MANUFACTURING SECTOR

Manufacturing environments are often filled with hazards, from sharp machinery components and materials to exposure to noxious chemicals and high noise levels. This way, workers should consider PPE not just a matter of routine but as a line of defense against the various challenges that they encounter during their workday.

This way, PPE Inspections are an integral part of safety protocols in manufacturing companies. Their main goal is to ensure that these protective layers remain strong, adequate, and ready to action to face all the shop floor challenges that may appear.

Worldwide, workers suffer approximately 250 million occupational accidents and 160 million occupational diseases each year.”

International Labour Organization

During these inspections is normal to visually check PPE items for wear, damage, and fit. Inspectors assess the functionality of the equipment and ensure the integrity of seals and straps. Depending on the equipment they can also verify expiration dates and certification labels. This comprehensive procedure guarantees the ongoing workers’ safety.

WHEN IS IT DONE?

Timing is crucial in PPE inspections. They can be conducted on several key times such as pre-shift assessments, post-incident examinations, and most importantly, as part of routine inspections. Regular checks of PPE before each shift or workday are key to ensure everything is in proper condition. The frequency of inspections may vary depending on workplace policies, the type of PPE, and the level of risk involved in specific tasks.

WHY IS IT DONE?

PPE inspections are conducted for multiple essential reasons. The primary reason is to safeguard workers’ safety and well-being. Confirming that their PPE is in optimal condition and provides the necessary protection helps reduce workplace risks. In addition, these inspections are also conducted to adhere to regulations, maintain operational efficiency, boost employee confidence, and provide a basis for ongoing safety improvements.

BENEFITS OF PPE INSPECTIONS

PPE inspections in an industrial context not only protect the well-being of workers but also promote compliance, efficiency, and a safer and more productive work environment. Here are some of the key advantages of conducting this procedure:

Risk Reduction

PPE inspections ensure that workers have reliable and effective protective equipment, reducing and preventing the risk of workplace injuries and accidents.

Operational Continuity

Regular inspections help minimize downtime caused by acidents due to the incorrect use of PPE or PPE failures. This way it is possible to maintain productivity and workflow consistency.

Data-Driven Decision Making

Data collected during inspections can be used to make informed decisions regarding safety improvements. For example, protective equipment upgrades or workplace risk mitigation measures.

Safety Culture & Improved Morale

PPE inspections contribute to the development of a culture of safety and continuous improvement. Knowing that their safety is a top priority, workers’ job satisfaction and confidence increase.

MAIN CHALLENGES

Conducting thorough PPE inspections in an industrial environment is crucial. However, it can be challenging for organisations to implement this procedure in their daily operations. Here are some examples of those challenges:

Frequency and Consistency

Maintaining a regular schedule for PPE inspections and ensuring consistent methodology across different teams and locations can be challenging.

Coordination and Communication

Ensuring effective communication between inspectors, workers, and management regarding inspection results and necessary actions can be difficult to balance.

Record Keeping and Action Follow Up

Managing and organising the records of PPE inspections, including documenting findings and follow-up actions to improve equipment and processes can be time-consuming.

HOW DIGITALIZATION CAN IMPROVE YOUR PPE INSPECTION?

Digitalizing PPE Inspections can help your organisation to overcome the challenges listed above. It is possible to transform and revolutionise this procedure by digitalizing it with the new Augmented & Connected Worker platform.

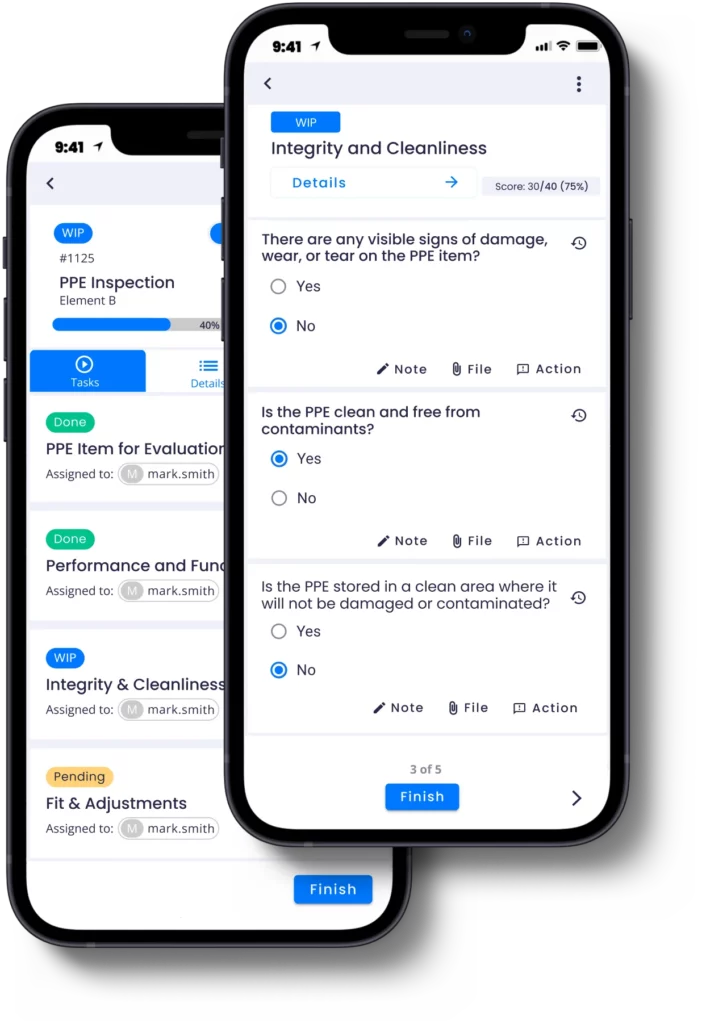

DIGITAL WORK ORDERS

Digitalising a PPE inspection helps streamline and simplify the entire procedure by eliminating all paper files, making the inspections more straightforward, consistent, and less prone to errors.

It also allows to schedule and organize inspections well in advance. This ensures that inspections are conducted at regular intervals and are planned without conflicting with other tasks or production schedules.

During execution, inspections are carried out with step-by-step guidance through intuitive checklists, accessible via mobile devices. This allows for enhanced consistency and procedure compliance between different departments and locations. It is even possible to introduce scored checklists to have a final inspection score. This quantifiable data provides a clear picture of the overall PPE condition and helps prioritise necessary actions.

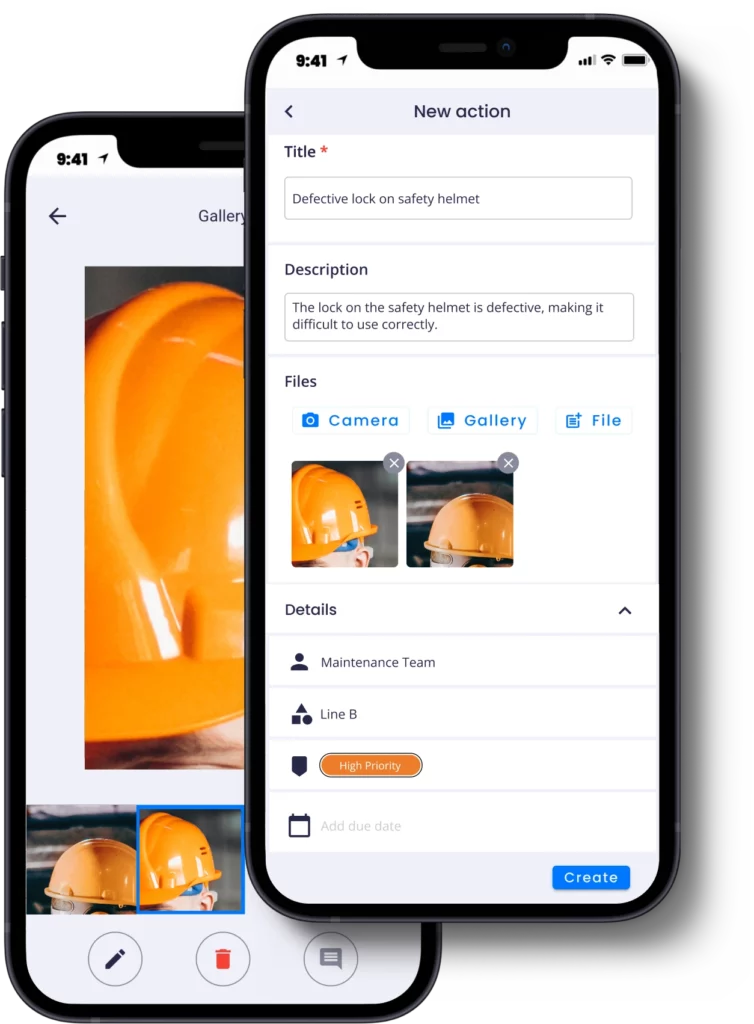

REAL-TIME DATA CAPTURE

Digitalised inspections facilitate seamless communication between inspectors, supervisors, and workers. Inspection results can be instantly shared, allowing for swift resolution of potential issues and quicker decision-making.

Enables real-time reporting of problems and issues identified during inspections. Inspectors can capture data, photos, and videos and send immediate alerts through actions to relevant personnel, such as supervisors, safety officers, or maintenance teams. This improves workplace safety by enabling efficient communication between teams and a fluid reporting of correctional and improvement measures to relevant personnel.

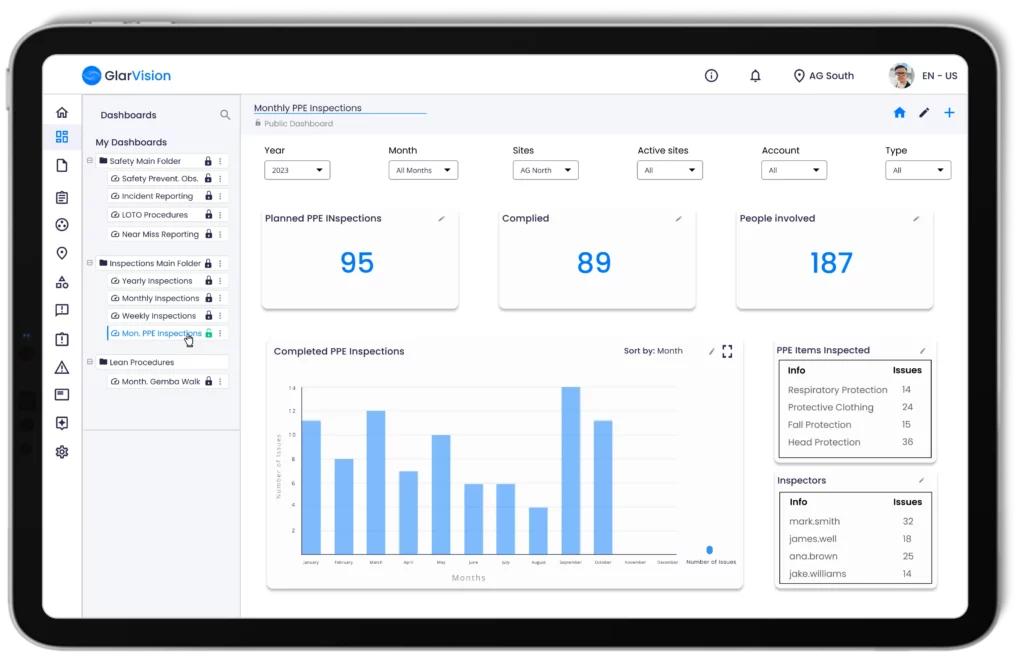

REAL-TIME MONITORING, ANALYTICS AND REPORTS

The Augmented & Connected Worker solution centralizes all information and simplifies data collection, allowing users to access information conveniently at all times. Data is instantly available, enabling real-time monitoring and making it possible to immediate responde to any safety concerns.

Analysis of collected data over time allows the identification of trends and areas of improvement, enabling proactive safety enhancements. All collected information is stored in extractable digital reports and can be used to conduct data analysis through dashboards, facilitating future audits and data-driven decisions.

HOW TO MIGRATE A PPE INSPECTION TEMPLATE TO THE PLATFORM?

Digitalizing a PPE inspection checklist is simple and can be done using the Augmented & Connected Worker platform. Using the back office you can create a digital procedure template.

Migrating the procedure checklist is easy due to a user-friendly form builder that allows users to replicate former paper instructions. It’s also possible to request varied types of questions with different response formats. You can also add conditional questions, scored questions, or ask for proof by requesting the upload of photographic evidence, among other features.

- Create a work order template (e.g.: PPE Inspection)

- Create your tasks (e.g.: Performance and functionality, Integrity and Cleanliness,…)

- Create your checklist and instructions (e.g.: Does the PPE meet the established safety requirements?)

- Create a work order using the previously created template

- Assign the work order to a team or person

IN CONCLUSION

In conclusion, PPE Inspections are a crucial part of organisations safety daily routines, allowing them to safeguard employees from potential workplace hazards. Overall, the transition of this procedure from paper to digital with the help of the Augmented & Connected Worker revolutionises the procedure, making it more efficient, compliant, accurate, and collaborative, ultimately leading to a safer workplace.

Want to learn more about PPE Inspections and other procedures that can be migrated from paper to digital? Visit our website procedures page and discover the Augmented & Connected Worker benefits. In addition. you can also request a PPE Inspection procedure template.

Learn More

Interested in learning more about digital solutions and how they are changing shop floors? Explore our use cases or reach out to our team to schedule a free demonstration to understand the full potential of Glartek’s Augmented & Connected Platform.