Inspect to perfect!

In today’s industrial environment, the association between proactive measures and operational success has never been more evident. With an increasing concern about raising quality standards, ensuring safety measures, and complying with regulatory processes, reactive measures are no longer enough. Instead, proactive measures are key. Among many proactive measures that organizations can take, self-inspection procedures have a crucial role in the pursuit of the objectives listed above.

With self-inspections, organizations take a hands-on approach to evaluate their own processes, infrastructures, and work conditions. This way it is possible to foster safety, ensure regulatory compliance, and maintain high-quality standards. The proactive nature of self-inspections in areas such as safety and quality has become not only a strategic choice but also an essential practice in safeguarding and optimizing operations.

SELF-INSPECTIONS IN THE MANUFACTURING SECTOR

Within manufacturing environments, self-inspections hold significant importance. The integration of this proactive approach practice emerges as a strategy that involves internal assessments to ensure adherence to safety regulations, quality standards, regulatory compliance, and operational efficiency.

WHEN IS IT DONE?

Self-inspection is typically conducted at regular intervals throughout the manufacturing process. These intervals may be defined by regulatory requirements, industry standards, or by the organization’s internal quality management system. The frequency of self-inspections may also vary based on the complexity of the manufacturing processes and according to the hazard level of the materials or conditions used to produce certain products.

WHY IS IT DONE?

The main purpose of self-inspections is to detect and solve deviations from determined standards and procedures. By conducting regular self-inspections, it is possible to ensure that processes are in line with regulatory requirements, leading to a safe work environment and producing high-quality products. This way, self-inspections contribute to a culture of continuous improvement, implementing a proactive approach to safety and quality assurance.

KEY BENEFITS

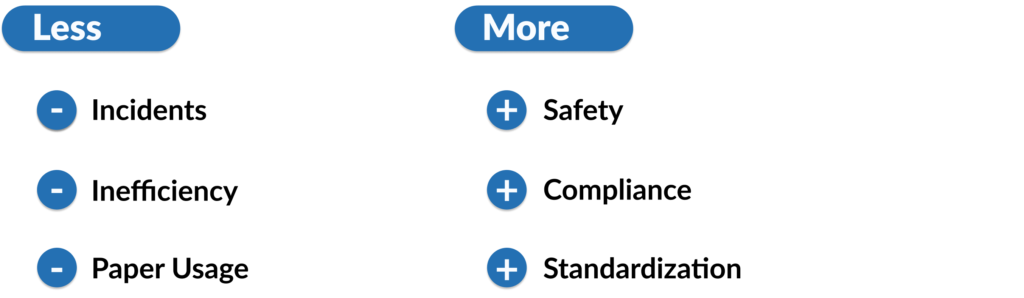

Self-inspections in an industrial context provide considerable benefits for organizations. They serve as a proactive measure to identify and mitigate potential issues. This way, this procedure is not only capable of improving safety and quality standards but also enhances operational efficiency and performance. Here are some of the key advantages of conducting self-inspections:

Safety and Quality Enhancement

Self-inspections help identify potential safety hazards and deviations from quality standards, allowing the implementation of fast corrective actions to prevent incidents and quality downgrades.

Compliance Assurance

This kind of inspection ensures that industry operations adhere to regulatory standards and compliance requirements, reducing the risk of sanctions and legal issues.

Operational Efficiency

By proactively identifying and addressing issues, self-inspections contribute to improved operational efficiency, reducing downtime, and optimizing processes.

Reputation Management

Demonstrating a commitment to safety and quality through regular self-inspections contributes to a positive industry reputation. This can be crucial for customer trust and stakeholder relations.

Continuous Improvement

Self-Inspections provide valuable insights for continuous improvement initiatives, allowing organizations to evolve and adapt to best practices.

MAIN CHALLENGES

In an industrial context, self-inspections are essential, however, the correct implementation of these procedures often comes with some inherent difficulties. Here are some examples of those challenges:

Lack of Standardization

Inconsistent approaches to self-inspections across different departments or locations can result in different levels of accuracy and compliance.

Maintain Frequency and Diligence

Maintaining regular and objective self-inspections can be challenging once that routine can lead to a sense of complacency where employees become less vigilant for potential issues.

Legal and Regulatory Updates

Keeping up with evolving regulations and ensuring that the self-inspection process remains compliant and always up-to-date with new rules and requirements can become a challenge.

HOW DIGITALIZATION CAN IMPROVE YOUR SELF-INSPECTION?

With the new Augmented & Connected Worker platform, it is possible to transform and revolutionize self-inspections by digitalizing them. The digitalization of these inspections will help organizations overcome several challenges related to procedure standardization, management, and legal compliance. It will not only streamline the entire process but also empower organizations to adapt and improve continuously.

DIGITAL INSTRUCTION

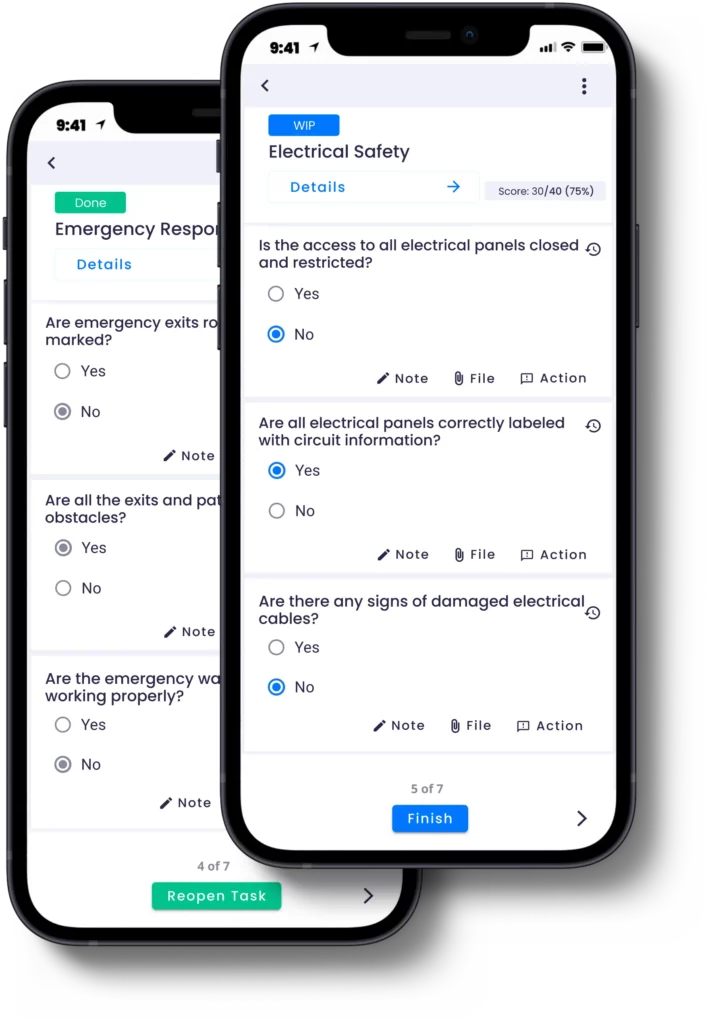

By digitalizing a self-inspection procedure, the platform helps streamline and standardize the entire procedure. With the help of digital work instructions and scored checklists, the platform improves inspection consistency and facilitates a more comprehensive and reliable assessment.

In addition, the Augmented & Connected Worker enables the adjustment to the procedure tasks or instructions whenever necessary in order to always comply with new legal or regulatory content.

ENHANCED WORKFLOWS

The platform helps managers to schedule and organize inspections in advance. This ensures that self-inspections are conducted regularly and in a timely manner, preventing lapses in the inspection schedule or conflicts with other tasks.

During execution, it also enables real-time reporting of potential issues identified. Inspectors are able to capture data in a fast a simple way, from text descriptions to photos and videos. It is even possible to trigger immediate alerts through the creation of actions assigned to specialized personnel regarding urgent issues.

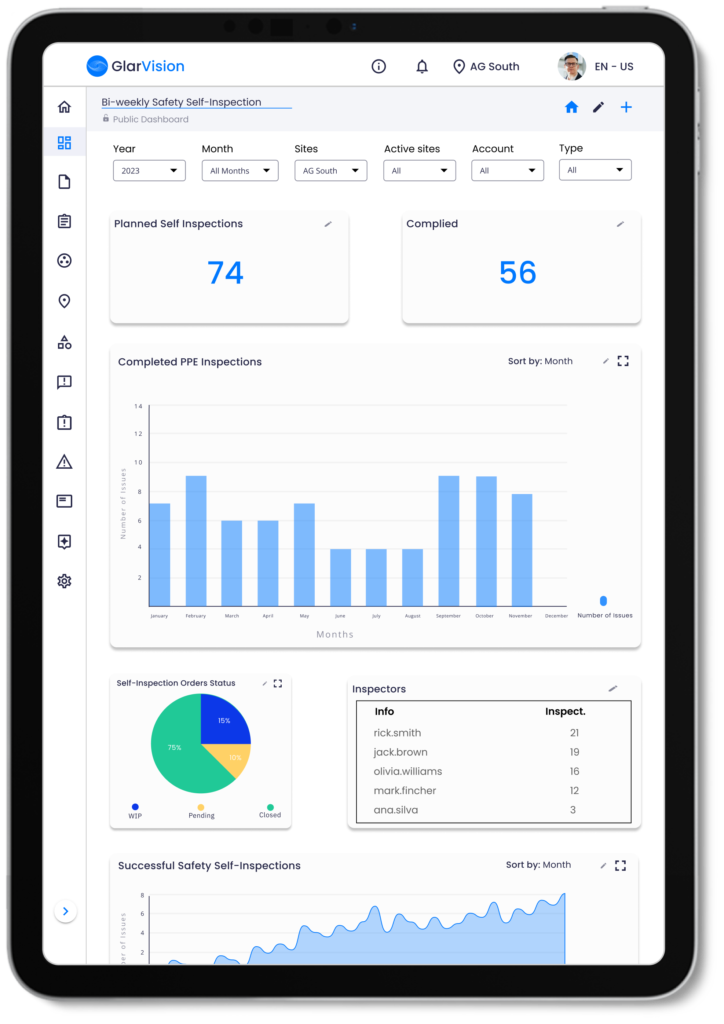

REAL-TIME MONITORING, REPORTS, AND DASHBOARDS

Glartek’s solution centralizes all information and simplifies data collection. Enables monitoring procedures that are being executed on the shop floor in real-time, while allowing access to relevant data regarding those procedures.

The Augmented & Connected Worker platform also enables data analysis, allowing the identification of areas of improvement, and proactive safety enhancements. All information is stored and extractable through digital reports that can later be used to create useful dashboards facilitating data-driven decisions.

HOW TO MIGRATE A SELF-INSPECTION TO THE PLATFORM?

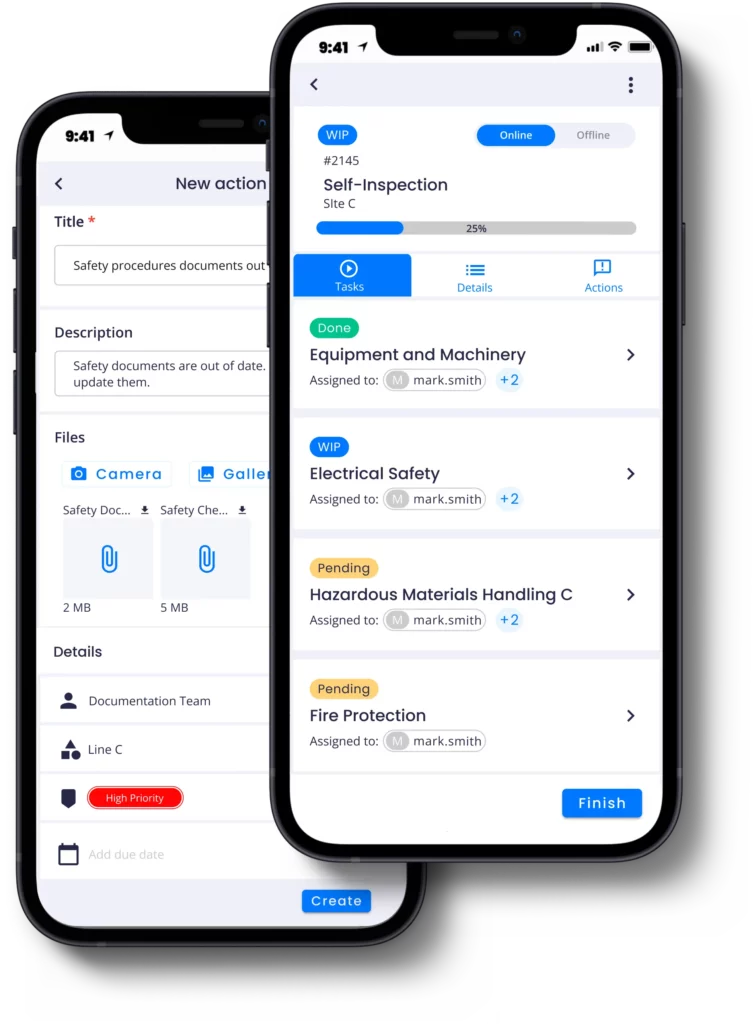

Digitalizing a self-inspection inspection checklist is simple and can be done using the Augmented & Connected Worker platform. Using the back office you can create a digital procedure template.

Migrating the procedure checklist is easy due to a user-friendly form builder that allows users to replicate former paper instructions. It’s also possible to request varied types of questions with different response formats. You can also add conditional questions, scored questions, or ask for proof by requesting the upload of photos and videos, among other features.

- Create a work order template (e.g.: Self-Inspection)

- Create your tasks (e.g.: Emergency Response, Equipment and Machinery,…)

- Create your checklist and instructions (e.g.: Are machinery guards in place and functioning as intended? Upload a photo as evidence.)

- Create a work order using the previously created template

- Assign the work order to a team or person to execute it

- Monitor the procedure and analyse the results

IN CONCLUSION

In conclusion, self-inspections are a crucial part of organization’s’ proactive measures, allowing them to improve continuously. Overall, the transition of this procedure from paper to digital with the help of the Augmented & Connected Worker revolutionizes the procedure, increasing the procedure efficiency, standardization, and accuracy, ultimately leading to a more compliant, safer, and productive workplace.

Want to learn more about Self-inspections and other procedures that can be migrated from paper to digital? Visit our website procedures page and discover the Augmented & Connected Worker benefits. In addition. you can also request a Self Inspection procedure template.

Learn More

Interested in learning more about digital solutions and how they are changing shop floors? Explore our use cases or reach out to our team to schedule a free demonstration to understand the full potential of Glartek’s Augmented & Connected Platform.