What is the 4M Analysis procedure?

4M Analysis is an example industrial use case method of problem-solving and risk management. This type of use case is very common in manufacturing and allows you to identify and classify the causes of a problem that impact a specific theme: Material, Method, Machine, Man.

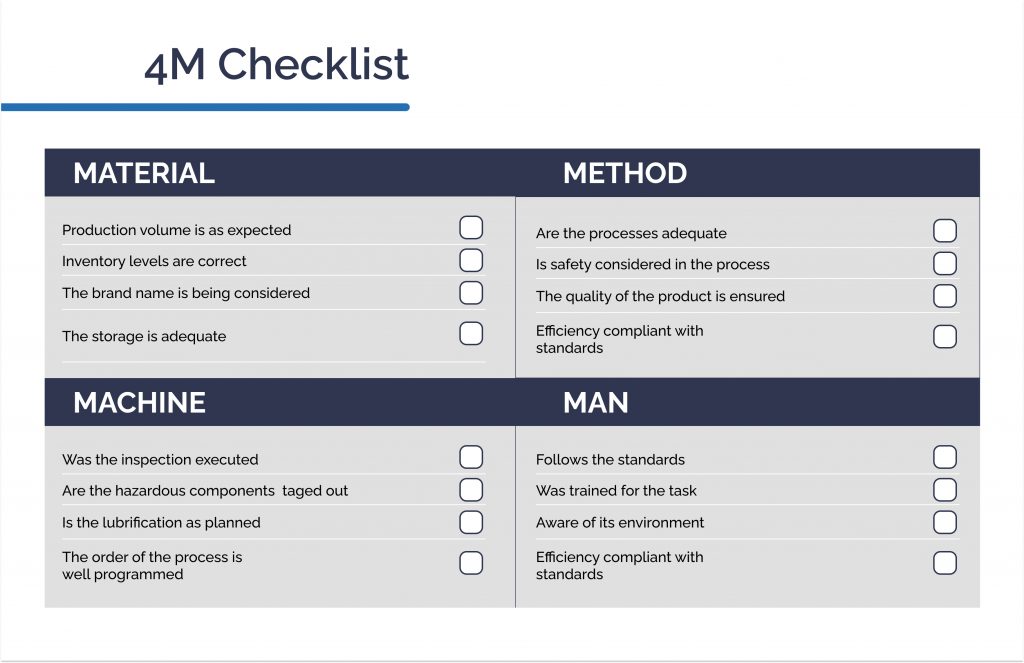

The procedure aims to analyze in a specific and detailed way a given process – that is causing a problem – and identify each of the “M” that may have contributed to this problem. Therefore, a paper checklist is created, printed, and provided to front-line workers so they can make the analysis and validate each important step of the way.

These lists include different checkpoints that workers must verify according to each M. For instance if the worker is being efficient if the amount of pieces produced by a machine is compliant with the planning, and much more checkpoints that must be verified.

After being filled by the front-line worker, the paper sheets are then delivered to the team leader, submitted on a computer program, and then analyzed by managers and directors

What are the benefits of using Industry 4.0 solutions to execute a 4M Analysis?

The implementation of this use case in the Industry 4.0 is supported by 2 steps:

- The first step is digitization. By digitizing the 4M Analysis process workers can access the information in real-time and help them in identifying the cause or causes of the problem.

- The second step is the creation of an advanced digital checklist directly on the shop floor to identify issues with any of the “M” and record them for future analysis. The checklist can be activated whenever needed and the content adjusted as required. And, is made available on the front-line workers’ devices, for example, mobile, tablets, or leading Augmented Reality (AR) glasses.

- At last but not least, managers and directors will be able to access information in the digital platform in real-time, extract automated reports, and create their own customized dashboards to improve decision-making support tools.

As Industry 4.0 has been entering our lives at a fast pace, we are facing a race to modernization. Companies must adapt their process to a new digital reality to keep competitive, and productive and to maintain an efficient front-line and office team.