In 2022, Industry 4.0 and its main tech trends continued to evolve and expand. The latest stage of industrial operations has been made possible by a set of new, innovative technologies and key transformations all across the industry.

To understand how the industry changed in the past year, we will be looking back at some of the main tech trends and highlights of 2022.

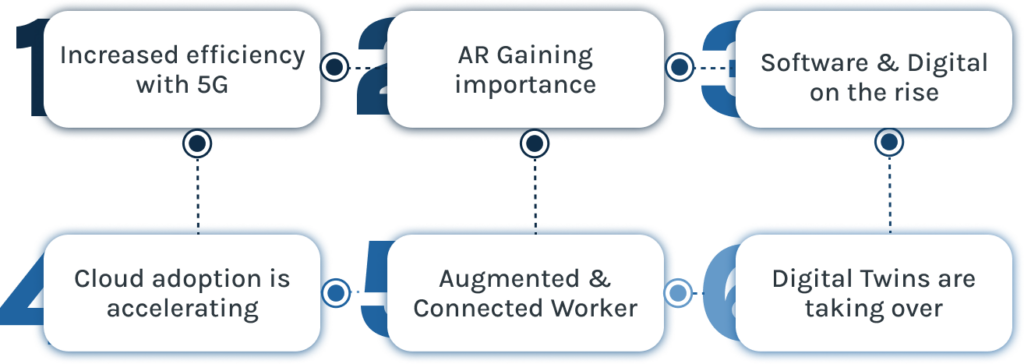

1 | INCREASED EFFICIENCY WITH 5G

5G is one of the main enablers of Industry 4.0, IIoT, and smart manufacturing. In 2022, these ultra-fast connections have reached 70 countries (32 more than in 2020), with Canada, the United States, and Europe leading mass deployment. Moreover, as a result of more devices compatible with 5G entering the market, it is estimated 5G has reached 1 billion users just 3.5 years after it was first released.

Private 5G networks are also one of the main tech trends in the industry. In essence, they help run digital solutions and applications while featuring increased security. Overall 5G bandwidth is already transforming industrial operations by making access to cloud data storage, communications, and live tracking faster and more accurate than ever.

5G also enables the creation of 5G factories, such as the one established using Glartek’s technology. This represents a new type of factory in which all aspects of production are connected. This allows for substantial increases in productivity, more efficiency, and faster production lines. In addition, workers are connected using mobile devices and can access information relating to all operations in real time.

2 | AUGMENTED REALITY IS INCREASINGLY IMPORTANT

Ever since Augmented Reality entered mainstream use in 2016, AR has steadily attracted more users and investment. According to Statista, the global AR market revenue was on track to earn $16.5 billion in 2022.

In 2022, AR expanded even further, starting with Microsoft’s release of the HoloLens 2 in the Indian market in January. According to Grand View Research, the global augmented and virtual reality manufacturing market size is expected to attain an annual growth rate (CAGR) of 29.3% from 2022 to 2030.

Industrial operations also continue to benefit from this technology. Frontline workers can access contextualized information (capable of guiding workers around shop floors), step-by-step guides, and augmented visual remote assistance (which provides an immersive remote assistance experience).

3 | SOFTWARE AND ACCESSIBLE DIGITAL SOLUTIONS ARE ON THE RISE

It comes as no surprise that software has been one of the key tech trends in industrial operations in the past few years. In the 2022 edition of the Hannover Messe, the biggest industrial fair in the world, software was the #1 topic. According to IoT Analytics, IoT platforms, automation software, and autonomous worker-enabling software were at the center of the event.

Moreover, individual software tools, common building blocks for digitization, and software platforms were also one of the main trends. Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES) software are no longer the only alternatives, as countless new digital solutions have been released in the past year alone. These new platforms help digitalize procedures, but also manage teams and track operations and results in real time.

Big players in the tech industry are also shifting the focus of some of their products to adapt to these new solutions. Companies such as Microsoft and Siemens have indicated their intentions to target specific goals, including efficiency and quality.

4 | CLOUD ADOPTION IS ACCELERATING

As Industry 4.0 continues to unravel, in 2022, cloud adoption continued to grow across the manufacturing and asset-intensive industries. According to Netwrix, cloud services are now a big part of companies’ daily routines. One of their recent surveys shows that companies expect “52% of workloads” to move to the cloud by late 2023”. This is a 17% increase when compared to the current numbers.

This data is further corroborated by Wipro FullStride Cloud Services’ report. The document indicates the European manufacturing Industry is leading the adoption of cloud solutions. In fact, data show that 30% of companies surveyed have reached “cloud leader” status. The report also points out that 79% of manufacturers consider cloud services have benefited the efficiency of quality control procedures.

5 | FURTHER RELEASES FOR THE AUGMENTED & CONNECTED WORKER PLATFORM

Augmented & Connected Worker (ACW) Platforms have also continued to introduce new functionalities. ACW platforms, including the one released by Glartek, introduced innovative features aimed at improving industrial efficiency, productivity, and safety. The ACW solution centralizes information, data, and documents all in one platform. This makes it possible to manage teams, schedule tasks, organize operations and procedures, set up workflows, and monitor tasks in real time.

Some of the main releases included new options to create alerts, send group notifications, import external files into the platform, customize AR markers, and download automatic reports.

In addition, visual remote assistance functionalities have also been expanded. Users can now contact experts directly, download session reports, and start video call sessions using more devices.

6 | DIGITAL TWINS ARE TAKING OVER

In 2021, several media outlets and industry insiders predicted digital twins to be one of the main trends in 2022. The interest surrounding this technology has been on a steady rise for the past 11 years, with Google searches increasing more than four times since 2011.

In addition, the digital twin market is also estimated to have hit $6.9 billion in worth in 2022. This value is expected to continue to grow in the next 5 years, landing at $73.5 billion by 2027.

When it comes to industrial operations, virtual replicas have the potential to reduce costs and substantially improve supply chain operations. Manufacturing can also leverage this technology for predictive maintenance and increase the adoption of Industry 4.0 principles.

LEARN MORE

If you’d like to learn more about Glartek’s solutions, be sure to visit our website or schedule a free demonstration. For more information on augmented reality and Industry 4.0, you can also explore our blog.